How to Select Injection Molding Services in China

Well, the major meeting has just concluded. your new product is a go, time is pressing, and the budget is, let’s say, constrained.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

You nod, of course. It makes sense on paper. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard the stories, haven’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

What belongs in your RFQ?

First, your 3D CAD files. They cannot be skipped. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

However, 3D alone won’t cut it. You also need detailed 2D drawings. Here you specify what 3D can’t show. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t label it simply “Plastic.” Nor just “ABS.” Get precise. Call out SABIC Cycolac MG38 (black), for example. Why so detailed? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

The Great Supplier Hunt

Now that your RFQ is pristine. who will you target? Online sourcing is global but crowded. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Consider using a sourcing agent. Yes, they take a cut. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. For a first-time project, this can be an invaluable safety net. Think of it as insurance for your project timeline.

Another tactic: trade exhibitions. With budget permitting, Chinaplas or similar shows are invaluable. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. And don’t forget the oldest trick in the book: referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How to proceed? It involves both metrics and gut feel.

Begin with responsiveness. Are their replies prompt and clear? Is their English good enough for complex technical discussions? But here’s the real test: Are they asking you intelligent questions? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Ask for a list of their equipment. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Then comes the audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s the best few hundred dollars you will ever spend on your project.

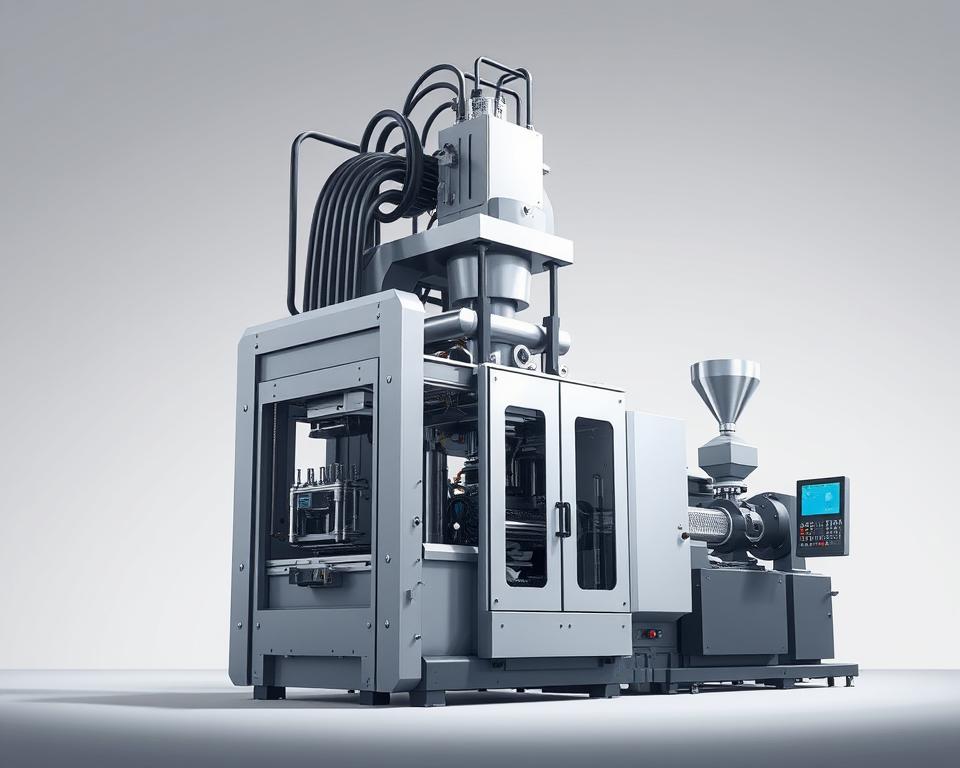

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Then comes the real action.

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. They are your moment of truth.

Expect T1s to need tweaks. That’s standard process. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold company samples follow. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How do you ensure that the 10,000th part is just as good as the golden sample?

Implement a robust QC plan. Often, you hire a pre-shipment inspection service. Bring in an external QC firm. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Know your shipping terms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.